Shares 2

Turbocharger In Motorcycle: How it Works?

Last updated on 01-Sep-2024 , By Shuvo

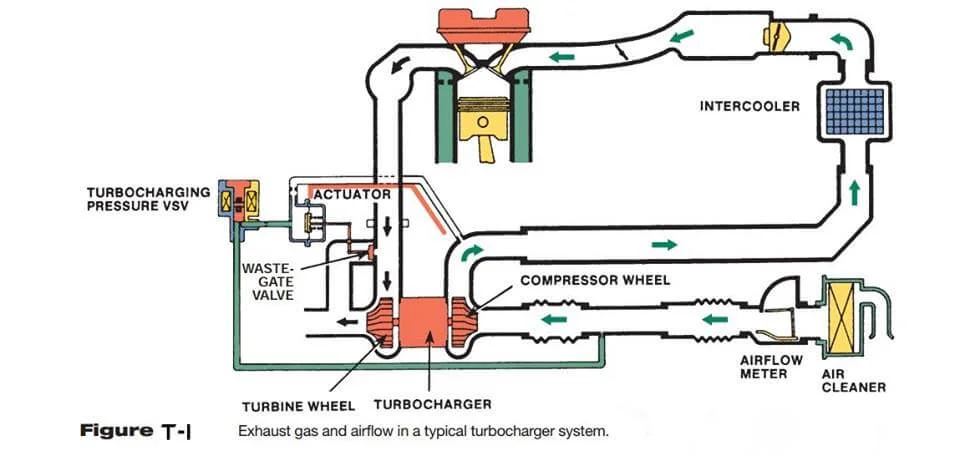

Turbocharger in motorcycle is used to increase engine power by compressing intake air before it enters the engine. Turbochargers are air pumps driven by the engine’s exhaust stream.

The heat and pressure of the exhaust gases spin the turbine blades (hence the name turbocharger) of the pump. The turbine wheel is connected to a compressor wheel. As the turbine spins, so does the compressor wheel. The compressor wheel spins at very high speeds and compresses the intake air.

The compressed air is then sent to the cylinders. Because exhaust gas is a waste product, the energy developed by the turbine is said to be free because it theoretically does not use any of the engine’s power it helps to produce.

Turbocharger In Motorcycle: How it Works? - BikeBD

Turbochargers are used on both diesel and gasoline engines. The main advantage of their use is that they allow for an increase of power without a substantial decrease in fuel economy.

Also Read: Motorcycle Polish & Shining Techniques

This is because they boost the engine’s power output only when extra power is needed. A small engine, in most cases, can be used to provide low fuel consumption and emissions levels. When increased power is needed, the turbocharger is activated.

Construction

A turbocharger is normally located close to the exhaust manifold. An exhaust pipe runs between the exhaust manifold and the turbine housing to carry the exhaust flow to the turbine wheel (Figure T-1). Another pipe connects the compressor housing intake to the throttle plate assembly or intake manifold.

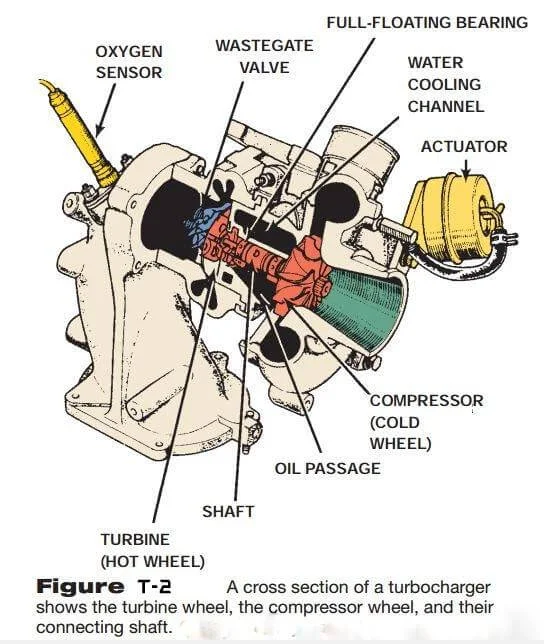

A typical turbocharger, usually called a turbo, has the following components (Figure T-2):

■ Turbine or hot wheel

■ Shaft

■ Compressor or cold wheel

■ Center housing and rotating assembly (CHRA)

■ Wastegate valve

■ Actuator

Inside the turbocharger, the turbine wheel (hot wheel) and the compressor wheel (cold wheel) are mounted on the same shaft. The CHRA houses the shaft, shaft bearings, turbine seal assembly, and compressor seal assembly. Each wheel is encased in its own spiral-shaped enclosure in the housing that serves to control and direct the flow of exhaust and intake air.

Because the turbine wheel is in the exhaust path, it gets very hot. It also spins at very high speeds; therefore, it is normally made of a heat-resistant cast iron. A turbocharger is equipped with a wastegate the compressor wheel (shaped like a turbine wheel in reverse) also starts to spin.

Intake air is drawn into the housing and is caught by the whirling blades of the compressor and thrown outward by centrifugal force. From there the air exits under pressure to the intake manifold and the individual cylinders.

Read The ownership Review who used a Turbocharger in His Yamaha Enticer. Click Here

Air is typically drawn into the cylinders by the difference in pressure between the atmosphere and engine vacuum. A turbocharger, however, is capable of pressurizing the intake charge above normal atmospheric pressure.

Turbo boost is the term used to describe the positive pressure increase created by a Turbocharger in motorcycle. For example, 10 psi of boost means the air is being fed into the engine at 24.7 psi (14.7 psi atmospheric plus 10 pounds of boost).

By-A.K.M.ABIDUR RAHMAN

T

Published by Shuvo