Shares 2

Motorbike Tire & Maintenance

Last updated on 31-Dec-2024 , By Shuvo

People learn from mistakes & we sometime experiment making mistakes. In the year 2014 Team BikeBD was quite busy with tours and test rides for some different class bikes in various locations in BD. That time we have experimented and experienced some issues related with bike wheel, tire, air pressure and some other related stuff. Hence summing up only few of them today here we are with Motorbike Tire & Maintenance.

You know there are different types of wheel; rim & tires are available in our market for our bikes. Generally we can segregate them as spoke & alloy rim and traditional tube tire & tubeless tires. Commonly tube tires are used in spoke rim and tubeless tires are used with alloy rim. Other than for some special characteristics like weigh, air friction, cost it has no ruling. Consequently you can see some hi-tech dirt or custom bikes with tubeless tires in spoke rim and some lower end bike with tube tire with alloy rim. Whatsoever we will discuss here for each type of rim, tires and of course some general issues.

Motorbike Rim:

You know about the spoke & alloy rims; both are successful in their segment and performing their job very nicely. Hence we will avoid broad discussion which is better as it depends upon various matters and also for which we have no choice to customize it for our bike as we the rides have limited range to choose from in Bangladesh where we can use only entry level lower displacement bikes. Therefore let’s discuss about the basic characteristics of both type of rim.

Spoke rim are generally made by solid steel plates and metal spokes are attached by bolt and washers with rim. Between the bolt-washer & tube there is also a thick rubber lining named rim which keeps them separated to avoid from friction. Spoke type rim is very tough to make it air proof because there are so many vents and loose end on the rim to hold the spokes.

Also Read: Gazi Tyre Mover (3.00-17) Tyre Price In Bangladesh

Therefore it is very tough to make each spoke joint sealed from air leakage. And for this reason spoke wheels are tube type. Only high end exclusive dirt bikes and customized choppers rim are prepared with sophisticated sealing to make them tubeless. Otherwise regular spoke rimes are only for traditional tube tire.

On the other hand alloy rims are designed with completely leak proof body where there are no spook to be attached with like bolt or washer and only five to twelve cast alloy arms do this job nicely where there are not a single hole on rim surface accept the air nozzle point. So alloy rim easily can be used for both tubeless & traditional tube tires.

Which Is Better?

The traditional spoke rim is light weighted; low priced and heavy distortion can be easily repaired. But easily get rusted in spoke joints & on tire bed, makes leakage on tubes and tire edge cracks quickly.

Also Read: Motorcycle Tire - Tubed vs Tubeless Tire Advantage & Disadvantages

On the other side alloy rim is little heavy, high priced, can tolerate heavy pressure but resistance is low and not repairable. But it keeps the tire nicely bedded in position within its lifetime. You can use tube or tubeless tires for longtime without any maintenance of the rim.

Hence the question which we want to avoid is which is better and for which feature. Simply spoke rim is nice for rural area & extreme off track where the wheel have to face heavy pressure on unpredictable surface. As spoke rim is multi-time repairable so it is perfect for the same.

And alloy rim is perfect for regular track bike and hi-speed high performance bikes where commonly tubeless self sealant technology can ensure maximum safety while even on high speed. And of course the pre-engineered alloy rim weight keeps the bike balanced & stuck on the on high speed which simultaneously works on effective braking. Therefore you can see most of the modern on-track bikes are with alloy rim with flat tubeless tires.

Tube or Tubeless?

Presently you can see many bikes are with tubeless tires on our . This is very simple feature as there is no tube inside the tire and the air hold only by the tire & rim; and this is tubeless. As you are known enough about the conventional tube tire there is no reason to discuss again. Consequently you may be curious what is the benefit of being tubeless and is it better from traditional tube tires? Yes tubeless tires are better option for high speed on track bikes. Let’s take a look on the reasons:

- No need for tube.

- No maintenance or alignment required for tube, rim or spoke.

- No scope to be flattened instantly on high speed which surely causes bike skidding & make accidents.

- Leakages are easily repairable and sometime you no need to untie the wheel mechanism.

- Self sealing is possible.

- Most of the times no need to repair the tire on the sport.

- Hassle free operation & low maintenance.

Repairing Method:

You know the conventional repairing method of old tube tires like disband the wheel mechanism, remove the tire from rim, pull out the tube, detect the leakage, trim & smoothen the leaked surface and vulcanize the same, tire for nails, tuck inside the tire, the rim for sharp end, the rim for fissure, blow some power inside the tire and reassemble the tube-tire & wheel mechanism. J But tubeless tire repair is not a hassle like this. And most of the times you need not to repair the leak on the spot.

Read This Important Article>> Tire Break In Period- Do You know It?

You can repair tubeless tires in various ways. You can use self sealant gel layer, can repair the tire disbanding the wheel or can repair the tire outside which called on wheel repair. Let’s discuss on each.

Self Sealing:

Self sealing tires widely used in foreign markets where still not available in BD market. But some motorbike company in BD selling their bike with self sealing tires which is only available with their bike (Example: UM Motorbikes) . In self sealing tires there are very soft rubber layer inside the tire crown wall which instantly jam off the leakage and seals the same. You can also enjoy self sealing technology with your regular tubeless tires where it is effective for less then 2.0mm wide leakages and you have to use nitrogen gas to keep the tires pressure stable as the air nozzle also get jammed.

There are self sealant gels available in our market for tubeless tires. But you have to be known that is not permanent solution for the leakage as it can blow out while you are running for long and long with high speed or in hot weather. So you need to repair the leakage permanently from inside of the tire while you are free.

Conventional Sealing:

This is the permanent sealing system for all type of tire leakage which we summarized previously. And you know that is the most reliable method of sealing to face every worst situation on tarmac. So while you are free, regain your tire strength with traditional sealing like tucking or vulcanizing from inside the tire.

Punch Sealing:

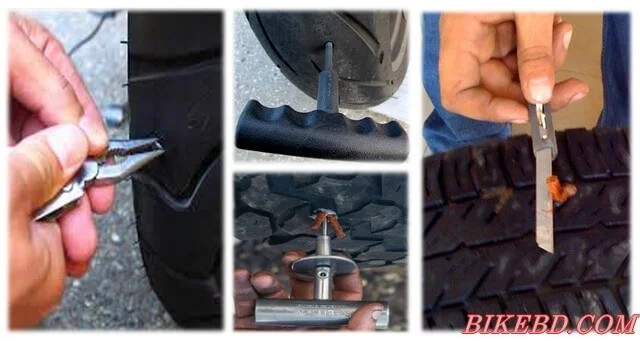

You can also repair tubeless tires instantly on wheel outside from the tire where you do not need to disband the wheel mechanism. Just pull out the culprit nail, trim & clean the vent with trimming nail, apply adhesive solution on the sealing plug, push hard the plug inside the vent and cut off the access, that’s it. This is a simple and hassle free sealing technique.

But truthfully this is not a reliable & permanent sealing technique for any hardcore biker as it tents to blow out the sealing plug when the rider runs for hour on cruel summer or uneven track. This type of sealing comes out due to hot tire temperature while running, over or increased air pressure and melting out the plug due to continuous friction with tarmac. So while you are on urgent situation only then you can apply punch sealing as temporary solution.

Which Is Better Technique?

You can see the traditional sealing technique is quite time consuming and hassle full job but this is most reliable technique to most of leakage of tire or tube. However self sealing and punch sealing is hassle free but truthfully a temporary sealing and in practical those are applicable for below 2 mm leakages.

The worst thing is most of the time the leakage dose not remain in size and widen by the time due to heat & increased air pressure and blows out the punched plug. And situation goes out of control while applied with old & worn tires. So apply those technique or solution while you are in urgent situation and try to with traditional sealing procedure.

Important! Recommended PSI:

Surprisingly most of the bike user posses some confusion and misunderstandings about air pressure of tire. They sometime use to ask which is correct PSI (Pounds per square inch) for their bike tires. After the time you may informed them about the right PSI which are marked before their eyes on bike swing arm or chain cover or tire wall or owners manual; they completely forget about it.

And again they remain in confusion that air pressure is not sufficient and insist to reach at more PSI. Resulting they face comparatively nice acceleration and unfortunately faces very poor suspension, ridiculously poor & risky braking, foolish sudden skidding on the and of course lower tire life. They never experience smooth cornering that’s for sure.

So do not be hungry for more PSI. Put your tire around recommended PSI. Don’t ask anyone foolishly. Just smartly see on owner manual, tire wall or swing arm of your bike. The accurate PSI is brightly marked on there. While you are with recommended air pressure you will get optimum suspension, braking power, skid free cornering, smooth operation of bike and for sure the longer & safe life of the tires.

Tire Replacement:

This is really an important issue. Some of us do not care about the replacement of tires. Maybe you do not ride much and the tire crown of your bike has not decayed much and still there are some grooves. But you have to know every material has own life time which expires after a period and loses its temperament and some time goes out of safe limit.

While you have passed its lifetime and it may showing like new but it may have reached to its expiry limit and that is too much risky for you especially for tire issues. So be careful. Change the tires after every four years even it has not used for much. But you should replace them early while the grooves decayed out of safe limit which are marked on tire grooves with TWI (Tire Wear Indicator) mark and also mentioned in your bike owner manual.

Important Article>> A Little Basic about Tires

What To Do?

Guys we tried to discus some common issues related with tire & wheels. Let’s enlighten some basics which we should practice.

- Your bike might have spoke rim, if so color the inner wall of the rim thoroughly with synthetic primer color and then synthetic or paint. This type of color will give you bike rim longer & rust free life and omit the scope for leaking from inside due to heavy rust in rainy season.

- Apply the mentioned color layer also for alloy rim if you wish to apply self sealing liquid as some liquid tends to react chemically and harms for the rim inner wall.

- Try to use nitrogen gas instead of solid air while using self sealing liquid as it also jam the air nozzle and you can’t blow out excessive air pressure while it hot. Nitrogen increases very little in hot in compare with solid air.

- rim & replace the same while it worn. Try to use thicker & wider for safety.

- If the leakage is over 2mm and you have repaired it urgently with punching, it again from inside of the tire while you are free. It is mandatory for your safety if you are often tending to ride long.

- Keep extra tube with you while you are moving for long even with tubeless tires. It really helps on sudden situation.

- Keep instant tire repair kit while you are on off-track.

What To Avoid?

- Avoid self sealing gel in tube tires. It’s not reliable with 1.5-2.5mm thin material like tube.

- Do not depend only on self sealing while you are planned for running long.

- Try to avoid temporary solution rather go for vulcanizing the tube or plug sealing from inside the tire.

- Do not apply tubeless mechanism with spooked rim. This type of mechanism is not reliable and can cause accident on the .

- Do not make the wheel tubeless just removing out the tube. Only tubeless categorized tire should use for tubeless wheels. Removing the tube out does not give actual performance of tubeless wheel. Never do it.

- Do not apply over air pressure than recommended. You will lose every aspect.

- Do not try to repair alloy rims at any situation. Just replace that.

- Avoid experimenting with wheel, rim & tire.

So guys we tried to give you a basic picture considering “Motorbike Tire & Maintenance”. Hope it will be helpful for you. Remember tire & wheel is an important & sensitive part of any bike which directly related with your safety. So don’t be over smart considering this issue and always be smart following the owner manual of the bike. Please share your thoughts & experiences with us with bellow commentary box or on our FB page. Thanks.

T

Published by Shuvo